The Netherlands are about the same size as Switzerland, and yet the country is the world’s second-largest exporter of agricultural products – right behind the United States, a country 230 times larger. Dutch farmers have mastered the art of extracting maximum value from their farms:

- 1.6 million dairy cows on 16,000 dairy farms,

- 11 million pigs on 3,000 pig fattening farms,

- 49 million broilers.

However, with the solid dung and the urine from their dairy cows, pigs, and broilers, Dutch farmers also produce a maximum of emissions: air pollutant ammonia (NH3) as well as the “greenhouse gases” methane (CH4) and nitrous oxide (N2O).

It is thus no coincident that a Dutch robotics manufacturer, Lely, has been searching for technological solutions to lower emissions without diminishing productivity.

Lely develops optimized barn floors and dung-collecting robots

Lely did not have to start from scratch. Apart from their well-known automatic milking systems, Lely has been producing the Discovery barn cleaner since 2005 and the Discovery Collector since 2017. Both manure robots clean the barn floor, while the Collector also sucks up dung and urine.

If the Collector simply disposed of feces and urine in a pit, the emissions issue would only be deferred. Lely’s engineers thus tried to find a way to actually reduce emissions and, at the same time, make use of the precious manure.

How the Lely Sphere manure-handling system works

Lely Sphere is a circular manure-handling system. Solid dung and urine are separated and converted into three mineral streams:

- fertilizer-grade mineral nitrogen in the Lely Sphere module’s washing water,

- phosphate and organic nitrogen in the solid waster (feces), and

- potassium in the liquid waste collected in the pit (urine).

Slatted floors are retrofitted with stainless-steel separation strips. Urine trickles through the holes in the separation strips into the urine pit, while excrement remains on the floor surface.

The Lely Sphere module vacuums off the urine’s gases from the barn

The Lely Sphere module is installed outside the barn. As a result of the negative pressure inside, it vacuums off gases that originate below or just above the barn floor.

With its low pressure and the separation strips, the system operates like an upside-down exhaust hood. A key factor these days: It requires only a small amount of ventilation capacity, compared to other air washer solutions.

This is the first step on the way to reducing emissions, since ammonia is formed shortly after the cow urinates. This natural process is triggered by the enzymes present in the feces.

The Lely Discovery Collector dung-collection robot gathers thick slurry consisting of feces and litter

In a second step, the feces and litter on the floor are not pushed away by the Lely Discovery Collector robot, but – as the name implies – collected and transported to a disposal pit, which is under negative pressure.

The Collector not only cleans the floor but also keeps the cows’ hooves clean.

The thick slurry consisting of feces and litter is stored in the disposal pit, separated from the urine, which opens additional options for an optimized use of the various mineral streams.

“You might stir the slurry, but it is very viscous. Separation is thus preferable, allowing solid manure to be spread on the fields, in addition to slurry,” says Curdin Giger, head of marketing and communications at the Swiss Lely Center. Due to the higher share of solid substances, the separation becomes cheaper.

Lely Sphere turns ammonia into precious fertilizer

The Lely Sphere creates negative pressure in the urine pit, separating the air that is sucked in from the urine’s fermentation gases.

With the underpressurized air only able to escape through a filter, the Lely Sphere N-Capture, by means of a solution acidified with nitric or sulfuric acid, extracts nitrogen (= N) from the air, from which a liquid nitrogen fertilizer is produced.

The liquid nitrogen fertilizer (ammonium nitrate or sulfate, depending on the acid used in the process) is stored in a special fertilizer silo and may be spread on fields as needed.

On a standard slatted floor, 13 kilograms (28.7 lbs.) of nitrogen per grazing livestock unit (GLU) are lost every year in the form of ammonia. The European GLU compares various farm animals on the basis of their liveweight: one GLU equals an adult dairy cow with a mass of 500 kg (1,100 lbs.).

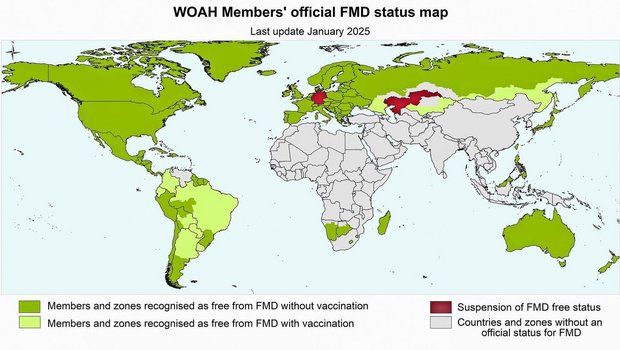

With remaining emissions of 3 kg (6.6 lbs.), the emission reduction amounts to 77 percent. At the same time, the system produces up to 20 kg (44 lbs.) of nitrogen per animal and year. The Lely Sphere is thus in compliance with the strict Dutch „Regeling ammoniak en veehouderij” (RAV), the “Regulation on ammonia and livestock farming.”

The output: urine slurry, dung, and washing solution

Giger expects a higher nutrient efficiency, since each farm is able to adjust their fertilizer to their individual needs and base the washing solution either on sulfuric or nitric acid.

Ideally, a farm might use, for example:

- urine slurry on pasture land (readily available water-soluble nitrogen, potassium),

- dung in agriculture (less readily available organically bound nitrogen, phosphorus),

- washing solution on pastures or grain fields (liquid nitrogen fertilizer).

The dosage can be tailored to the specific needs of each crop, and the farmer saves money on fertilizer purchases, since ammonia emissions that are absorbed and recycled into nitrogen fertilizer will not have to be offset by additional fertilizers bought separately.

Emission reduction will also improve air quality inside barns

The separation of feces and urine as well as the extraction of manure gases from the two pits also adds safety, since these harmful gases no longer accumulate in the pits and escape into the barn area.

This also freshens the air inside the barn. Natural ventilation in the barn is maintained, and cows are free to go in and out of the barn as they like. In addition to creating value from the dung, the Lely Sphere also provides a healthy climate in the barn and makes it safer for humans and animals alike.

In the Netherlands, 27 of these systems are currently in operation, several more in Germany and in Denmark, and from 2024, they will also be employed in Switzerland.

Future of Dutch agriculture uncertain

In 2022, the Netherlands exported agricultural products worth 85 billion euro (for comparison: exports from the United States, although 230 times larger, “only” amounted to €126 billion).

The agrarian sector accounted for 1.6 percent of the country’s GDP and employed two percent of its workforce.

Nearly 60 percent of agricultural products are exported, mainly potatoes, tomatoes, and other fruits and vegetables, followed by livestock and meat, flowers, dairy products, and eggs.

Dutch agriculture is characterized by monocultures with an extensive use of fertilizer and factory farming (including 16,000 dairy farms and 3,000 pig-fattening farms), which has a severe impact on the environment.

The Dutch government is currently implementing a restrictive nitrogen policy, which would result in a massive reduction of livestock and thus constitutes an existential threat to farmers.

Full Disclosure

Our magazine "die grüne" attended a presentation of the Lely Sphere in the Netherlands as part of a press trip organized by the European Network of Agricultural Journalists (ENAJ). Travel (by train) and accommodation expenses were covered by our editorial department, meals by the host.